What Is Sheet Metal Parts?

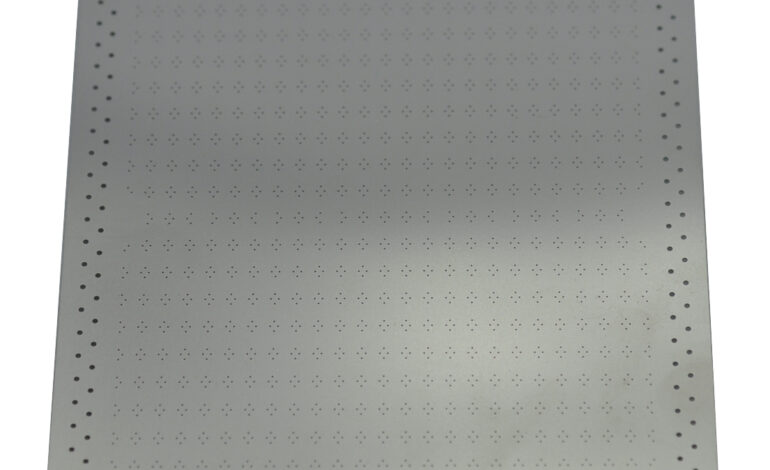

Sheet metal parts are models in sheet form that can vary in size, shape, and material. Sheet metal parts are often uniform in thickness and are easily modified by adding features such as chamfers, holes, and flanges. The material used to create sheet metal parts is malleable, making them suitable for complex and specialized applications. Here are the common types of sheet metal parts:

Bend allowances: In sheet metal parts, bend allowance is the amount of material added or subtracted to develop a flat pattern. In addition, the bend radii are the same throughout the part. This helps maintain uniform wall thickness, while maintaining proper dimensions. Another important factor to consider is the orientation of holes and slots in the part. The slots should be spaced evenly along the sheet metal thickness to reduce the possibility of bending the part.

Bend Relief: In sheet metal components, bend relief is often used to reduce the risk of metal tearing when bent. The flange should be formed perpendicular to the metal grain structure.

Tight tolerances: While these features are essential for accuracy, they can also lead to premature wear of punches. Coining, collars, and chamfers are additional features that improve the stability of the finished part and reduce the production time.

Replaceable: Sheet metal parts are the most economical way to modify or replace an assembly. These metal pieces can be easily removed from their assembly and replaced separately. Unlike other materials, sheet metal parts can be modified or upgraded easily without losing their strength. They are also cheaper than plastic tooling. A single sheet of metal can be shaped into almost any shape. In the automotive industry, sheet metal parts are crucial for many applications. The flexibility of this material makes it a popular choice among manufacturers and designers.

Brackets: Another useful sheet metal part is the bracket. Brackets can be fabricated in virtually any shape, from small to large, and they are often used for shelf applications. However, they can also be used for structural steel projects. These brackets are used to hold and secure various parts within an enclosure. And they can also be used for other purposes, such as in aircraft. These components can be used for everything from airplane wing ribs to jet engine exhaust systems.

Precision leveling: There are two basic methods of leveling sheet metal parts. The hammer and flame method is the easiest and simplest way. However, this method requires high-level skill, is time-consuming, and is best suited for small batches. Another option is the straightening press, which involves supporting the part at two points and pressing the material into a large die. This method also involves a rinse-and-repeat approach, and is similar to the hammer and flame method.

When designing a component, it is important to choose the right material for the project. Different materials have different properties. Selecting the right material will depend on the design, application, and requirements. Choosing the right material depends on formability, weldability, and strength. In general, uniform wall thickness is preferred when designing geometry. Using different wall thicknesses will result in different bend parameters, and it may not be the right shape for the application.

Welding and hemming are other common methods of joining sheet metal parts. Both processes use the same method, but a metallurgical bond is created that binds two sheets together. In aerospace, riveting terminology includes the manufacturer’s head, the shank, and the shop head. This makes it easier to repair damaged parts and assemble components. You may also want to consider the final application of the product before selecting a method for fastening.

There are many different types of manufacturing processes for sheet metal components. For mass production, mechanical shearing is the fastest method. In metal workshops, manual bending is used. The process is faster than laser cutting, but it is not as accurate as CNC cutting. Regardless of the method, sheet metal forming and fabrication is a popular and highly cost-efficient option. Depending on the material and thickness of the metal, it can be automatic or manually loaded.

For more information, visit RMT. We offer cost-effective sheet metal and plastic fabrication solutions. If you’re not an experienced sheet metal manufacturer, you can benefit from our expertise in manufacturing sheet metal components. Our experts can take your concept and make it into a reality. And if you’re not familiar with the process, consider these factors when choosing a company.