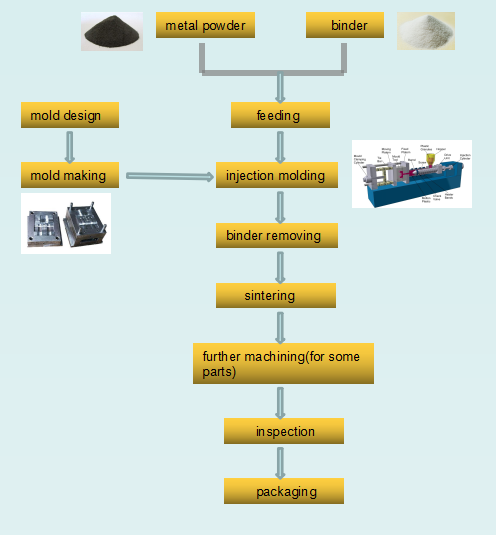

MIM Concept And Process Flow

Metal powder injection molding is a high-tech combination of traditional powder metallurgy technology and plastic injection molding technology. It is a revolution in the molding process of small and complex parts. It uniformly mixes the applicable technical powder and binder into a rheological feed, which is injection molded on an injection machine. The obtained blank is sintered and densified into a finished product after degreasing treatment, and can be post-processed if necessary.

The production process is as follows

Ingredients → mixing → granulation → injection molding → chemical extraction → high temperature debonding → sintering → post-processing → finished product

Application of MIM:

Metal powder injection molding has been widely used in mechanical industry, electronic industry, automobile industry, office automatic industry,

watch, photoelectric industry, military industry, medical devices etc.

● Computers and auxiliary facilities: printer parts, core, striker shaft pin, drive parts

● Tools: such as gun drill, drill chuck, power tools, hand tools, wrenches and other spare parts, milling heads, nozzles, etc.

● Household appliances: such as watch case, bracelet, electric toothbrushes, scissors, fans, golf head, simulation jewelry, tool heads and other parts;

● Medical equipment parts: dental orthopedic frame, orthopedic bracing parts, scissors, tweezers;

● Military ordnance parts: the missile tail, firearms parts, warheads, liner, Fuze parts;

● Electrical parts: such as micro-motor parts, electronic parts, sensors, cell phones etc.

● Mechanical Parts: complex parts such as small loose cotton, textile machines, sewing machines, office machinery, and other machinery parts;

● Automotive, marine parts: clutch inner ring, radial inserts, fork sets, distributor cover, car airbags, car locks;

● Oil drilling with various special-shaped carbide nozzles.